Aircraft livery design is far more than paint; it’s branding, advertising, and can be used as a form of storytelling, subtly telling onlookers about the history of the brand. From iconic airline colour schemes to bespoke promotional wraps, liveries help aircraft stand out in the skies and on the runway. But, behind the branding, colours, and marketing, there is hard work and professionalism, made possible by masking tapes from manufacturers like JTAPE.

Precision masking plays a key role in aircraft livery painting. It ensures crisp edges, prevents paint bleed and overspray, and keeps complex designs looking clean and professional. Without the right masking solution, a high-stakes paint job can fall apart, wasting time, costing money, and damaging reputation.

Aircraft livery: Art, engineering & regulations

Aircraft liveries serve several purposes in modern aviation. At the most basic level, they function as a branding tool. Airlines use liveries to create a strong identity, build customer recognition, and make their fleets instantly recognisable.

Beyond aesthetics, there are engineering and regulatory factors to consider. Aircraft paint plays a protective role, helping shield the surface from UV damage, moisture, and corrosion. Certain design features can also aid visibility and thermal management.

Most importantly, liveries must meet strict aviation regulations on reflectivity, positioning, and added weight.

Choosing masking tapes suitable for aircraft livery painting

Aircraft livery painting presents unique challenges because of the large-scale surfaces, specialist paints, and extreme environmental conditions. Not all masking products are built for aviation work, which is why selecting the right masking tape is crucial.

Common issues to avoid

If the wrong tape is used, problems are almost inevitable. Paint bleed is a common issue that can compromise the crispness of design edges. Overspray, where paint ends up on unintended areas, is another frequent headache. Then there’s the matter of residue, with low-grade tapes often leaving adhesive behind, especially after exposure to heat.

Particularly on aircraft, where regulations are strict and vital for safety, any additional residue or extra paint in unwanted areas can cause an aircraft to fail safety tests.

Ideal masking tape characteristics & properties

To meet the demands of aircraft livery painting, masking tapes need to be made to a high specification. High temperature resistance is essential, as many aviation paint systems involve baking cycles. Standard tapes aren’t enough for these applications; only heat-resistant tapes will hold their shape and adhesion.

Chemical resistance is another key consideration when painting aircraft. Aviation-grade paints are tough and can degrade weaker adhesives. A high-performance tape must also have properties such as flexibility and conformability, making it capable of hugging tight curves and contours without lifting or wrinkling.

If painting on the apron, UV-resistant tape is also an incredibly important aspect to consider. Without UV-resistance, tapes can degrade under the UV rays from the sun.

JTAPE masking solutions for painting aircraft livery

JTAPE offers a selection of premium masking solutions developed specifically for the challenges of aviation painting. Whether you’re creating a custom livery or handling a fleet-wide update, these products give you precision and dependability at every stage.

110°C High Performance UV Masking Tape

When working with aviation-grade paints, temperature and UV resistance should be a priority for your chosen masking products, which is why we recommend our 110°C High Performance UV Masking Tape. Perfect for all stages of aircraft livery painting, this masking solution features a specially formulated adhesive which creates a strong bond with different surface types without lifting.

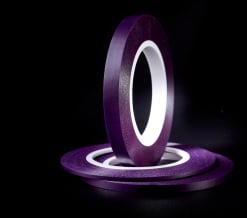

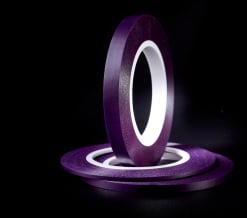

Purple Translucent Fine Line Masking Tape

Ideal for curved lines, complex patterns, and multi-tone liveries, Purple Translucent Fine Line Masking Tape gives you maximum control thanks to its translucent finish, allowing for precise alignment over templates or markings, helping you hit the mark every time.

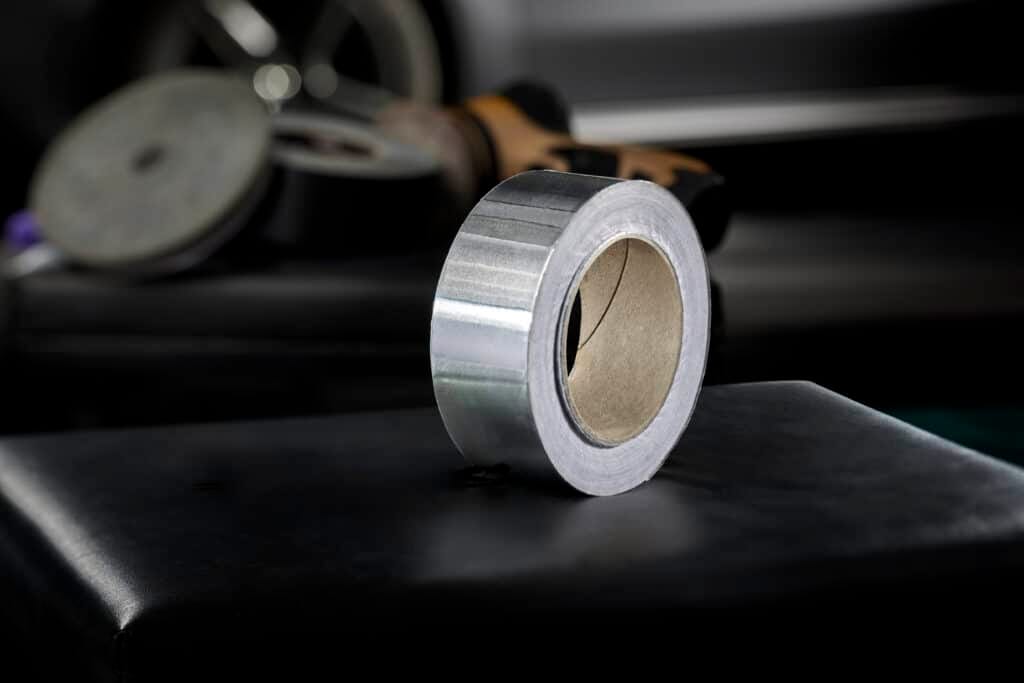

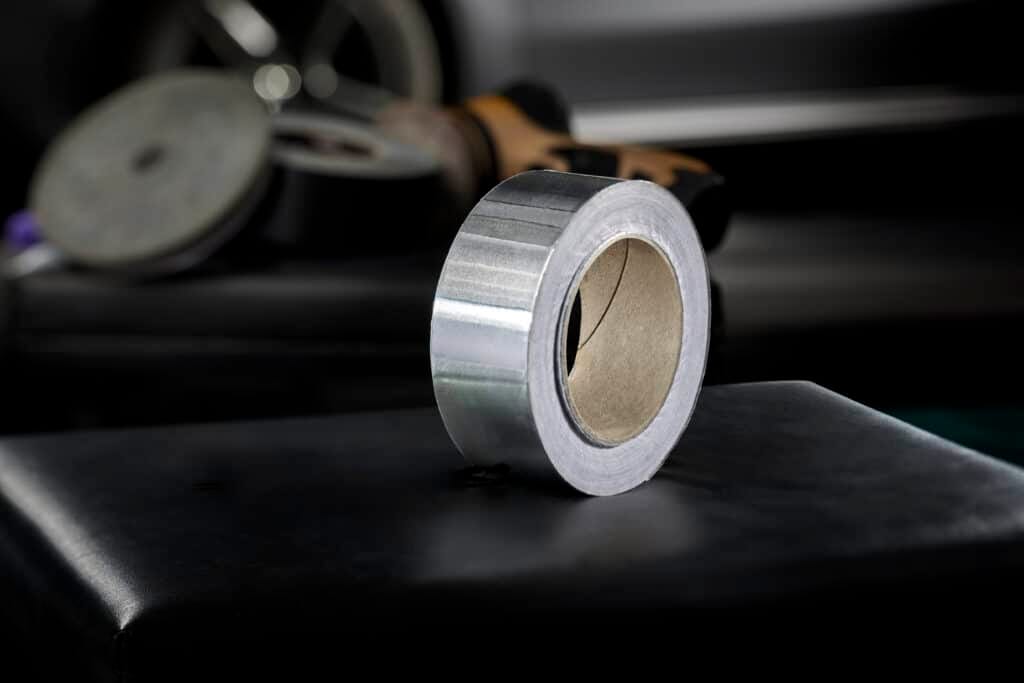

Aluminium Tape

With excellent durability, even in extreme conditions, our Aluminium Tape can be used to protect against damage when sanding adjacent surfaces, trims and rubbers. It’s ideal for use during the preparation stages in aircraft livery painting to help achieve a smooth base.

Red Premium Cloth Protection Tape

Red Premium Cloth Protection Tape does exactly what it says on the tin; it offers tough, durable protection for a variety of surfaces when sanding. Featuring 78 weaves per inch, this masking tape guarantees that your preparation work is clean and consistent.

We also offer black, blue and silver variations of our Premium Cloth Protection Tape, all of which are ideal for use in the aerospace industry.

Perforated Plus Trim Lifting Tape

Aerospace rubbers can be particularly difficult to mask due to the material they are made from. But thanks to the increased leverage offered by our Perforated Trim Lifting Tape, you can achieve perfect coverage and a clean paint edge every time.

Industry best practices for a professional finish in aircraft livery

Even with the right materials, achieving a perfect livery depends on following industry best practices. After painting, a detailed inspection is crucial. This ensures any flaws, such as paint bleed, missed sections, or overspray, are caught and corrected before the job is signed off.

Pacing is another important factor. Aircraft painting is not a job that can be rushed. From design and surface prep to masking, painting, and inspection, each stage demands care and attention. Skipping steps or rushing through them increases the risk of failure.

It’s also vital to properly mask off everything that’s not being painted. That includes windows, sensors, ports, lights, and electrical or mechanical components. Clean surfaces are a must, too; tape adhesion suffers on dirty or greasy areas.

Finally, always test your tape with the paint system you’ll be using. Even the best tapes behave differently depending on temperature, humidity, and surface material. A quick compatibility test can prevent costly surprises.

Aircraft livery is where precision meets creativity, and none of it works without reliable masking. JTAPE’s range of aviation-ready tapes gives professionals the tools they need to paint with confidence, whether the design is corporate, creative, or completely custom.