But when ductwork isn’t properly sealed, air leaks out, wasting energy, putting strain on systems, and leaving occupants feeling less than comfortable. That’s where aluminium foil tape makes all the difference.

With that in mind, let’s look at how you can properly use foil tape to ensure a quality and professional finish across all of your ductwork.

Why is aluminium tape used in ductwork?

Foil tape used for ductwork is instantly noticeable as being metallic, and there’s a good reason for that. Overhead ducts are frequently used for heating and ventilation systems that can get incredibly hot.

Foil tape is ideal for this kind of work because aluminium is a naturally insulating material that will prevent heat from escaping into the air before it’s supposed to.

Additionally, aluminium maintains its integrity in both hot and cold temperatures, allowing for fluctuations that will occur within a ventilation system. This ensures that seals remain effective and secure over time, while also contributing towards lower energy bills and achieving more consistent temperatures.

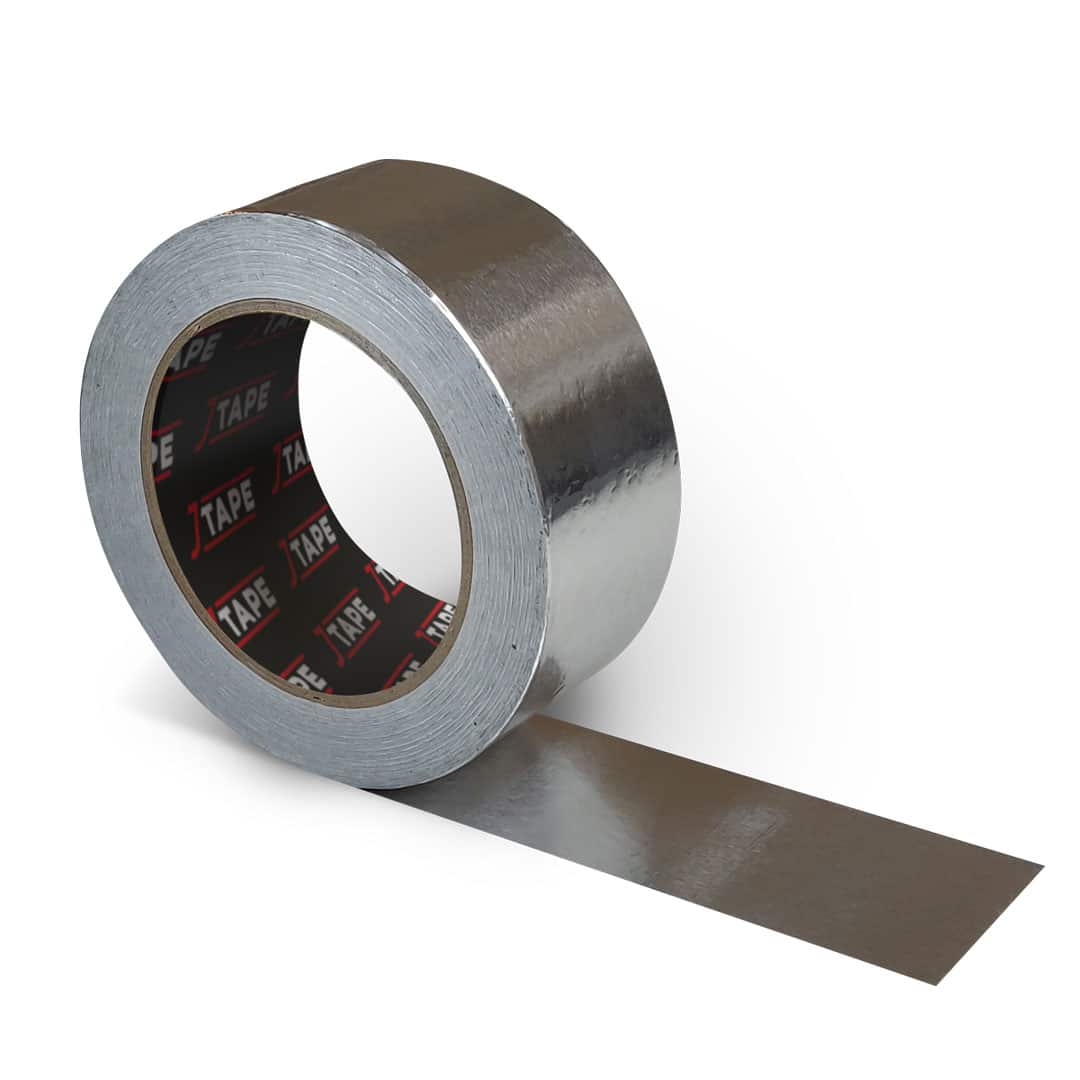

We have worked closely with professionals to develop JTAPE Aluminium Tape so that it meets the comprehensive needs of HVAC technicians.

How to use foil tape for ductwork

Using foil tape correctly is key to getting the best results. Here’s a simple step-by-step guide to help you apply it professionally.

Step 1: Prepare before taping

Before you begin, make sure the HVAC system is turned off to ensure safety during application. Clean and dry the surface thoroughly – dust, oil, or moisture can compromise the integrity of the tape. Correct surface preparation allows the tape to bond firmly, ensuring long-term durability and performance.

Step 2: Measure and cut to size

JTAPE’s aluminium tape includes a convenient silicone paper release liner, making it easy to measure and cut the tape to the exact size you need before applying it. Cut the tape into manageable lengths using sharp scissors or a precision blade. Smaller sections are easier to control and apply neatly, especially around awkward bends and corners in ductwork.

Step 3: Remove the release liner and apply to the area

Peel back the release liner and carefully apply the tape over the joint or seam. Make sure the tape is laid straight across the area for a clean seal. The synthetic adhesive bonds instantly with a strong adhesion of 6.5 N/cm on steel. Press down firmly as you go, smoothing out the tape to remove air pockets and avoid wrinkles.

Step 4: Seal and protect

Pay close attention to the edges – these need to be firmly sealed to keep moisture out and ensure the tape performs over time. Any gaps or lifted edges can compromise the seal and allow air or moisture in, so take the time to check.

Top tips for aluminium tape applications

To get the best performance from your foil tape, we’ve got a few helpful tips:

Overlap tape joints

When applying multiple pieces, make sure they overlap slightly to create a continuous, airtight barrier. This also prevents weak spots in the seal.

Always work on a clean, dry surface

It’s worth repeating that tape won’t stick to a dirty or damp surface. Wipe down the surface you intend to apply the tape to thoroughly before application.

Use a tool to flatten bubbles

A squeegee or roller can help press the tape down evenly and eliminate any trapped air for a smoother finish.

Don’t overstretch the tape

Stretching weakens the adhesive bond and can lead to lifting. Apply it flat and let the adhesive do the work.

Inspect and maintain regularly

Periodically check the taped areas as part of routine system maintenance. Replace or reseal any worn or lifting sections to maintain optimum performance.

Aluminium foil tape might seem like a small detail, but when it comes to ductwork performance, it makes a big impact. JTAPE’s Aluminium Tape delivers reliability, strength, and professional-grade performance for every sealing application.

JTAPE offers a wide range of products designed for industrial environments, from masking solutions to protective films and speciality tapes. Discover how JTAPE can support your next project by exploring our range of industrial tapes or contacting us to find out more.