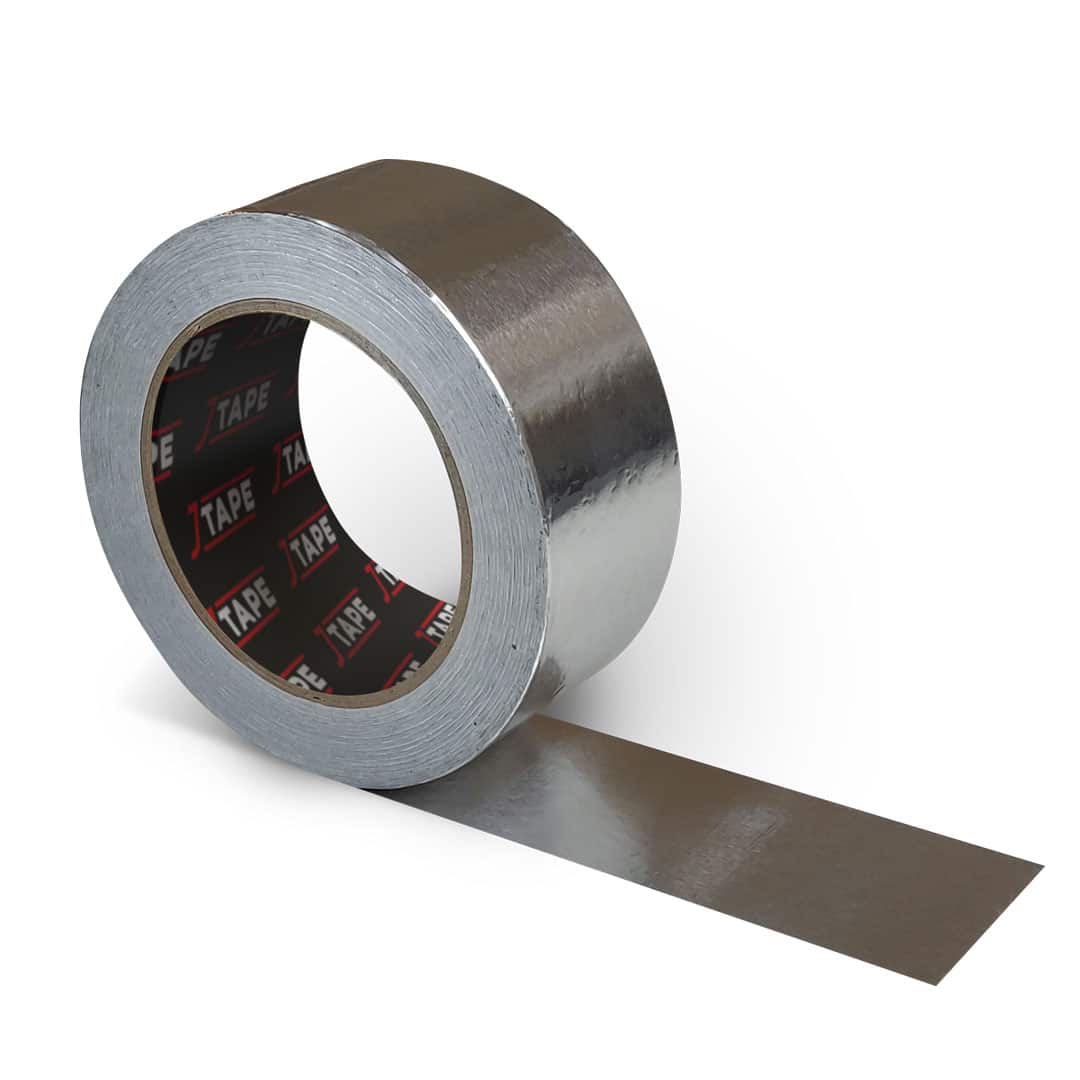

Cloth and protection tapes are typically used to create barriers, make temporary repairs, or provide light-duty seals. At JTAPE, we’ve manufactured a wide range of cloth and aluminium-backed protection tapes to help you find one that meets your needs.

Whether you need a simple high-tack cloth tape or aluminium tape to provide superior heat protection, our products are specifically designed for users from all different industries. Our premium tape solutions are the perfect addition to any toolkit, regardless of the materials you’re working with and the temperatures the tape needs to withstand.